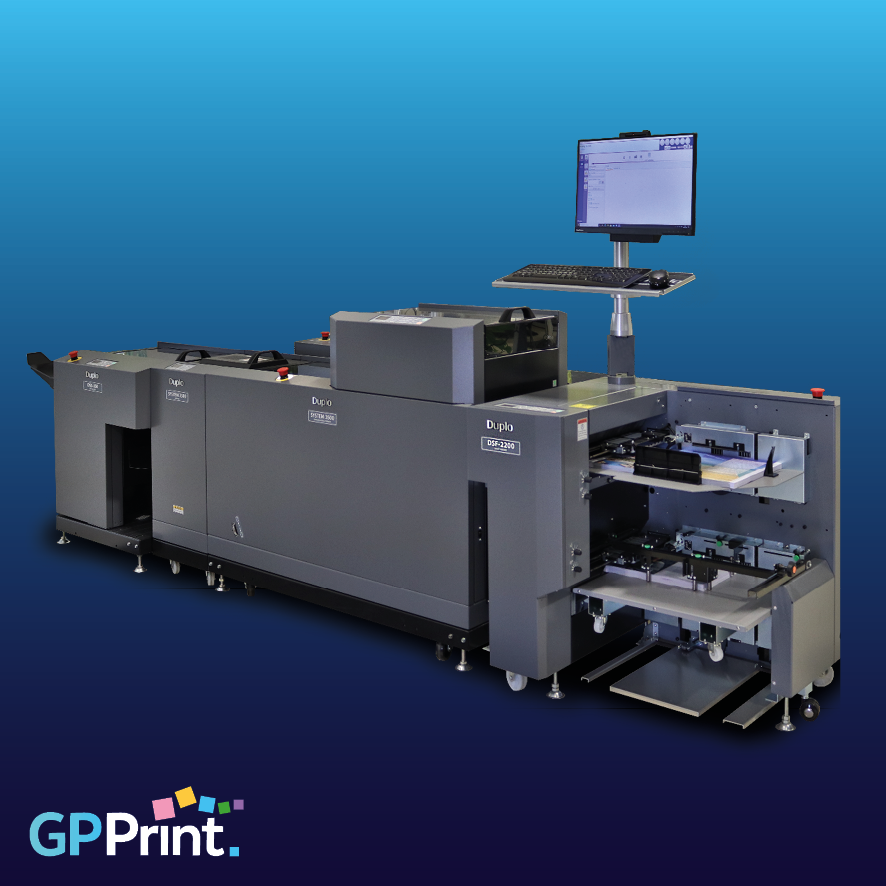

The DBM 350

Meet the DBM 350, our digital booklet system. With this latest addition to our kit list, we can complete a wide range of booklet options with ease. Before we bought this machine, we ran a booklet maker that required someone to stand over and hand feed the booklets into the machine one at a time. With this new machine, we can load and press go. Geared up for our digital operation, we can print the pages in order and let the machine do the rest.

We can produce booklet sizes of A4, A5, A6, A5 Landscape and custom sizes up to 20 sheets creating 80 pages.

The first station is the feeder which takes a sheet at a time feeding into the machine.

The second station is the stitching unit, which is what printers call the process that basically staples the pages together. It uses a wire feed which creates the staples so we don't have to keep loading a fresh batch.

The third unit folds the booklets in half making the booklets finally take shape.

The fourth unit taps the folded edge to help keep it flat and not spring open.

The fifth station trims off the edge to make it nice and square without feathering as one sheet inside another could sit prouder than the previous without trimming.

The last station is called a square back. This part pushes up against the spine and squares the edge. In doing this process, it ensures the booklet lays flat and doesn't spring open. Very much like the fifth unit but it applies the force on the side rather than the top.

Once completed, it ejects the booklets one by one, ready to be packed and handed over to the happy customer.

Along with the many investments we have made this last year, this machine allows us to streamline the business becoming more efficient and helping to keep the pricing as competitive as possible for our customers. Not only that, it can ensure we produce great quality products with ease each and every time.

Wide selection of booklets we can produce

Making Booklets