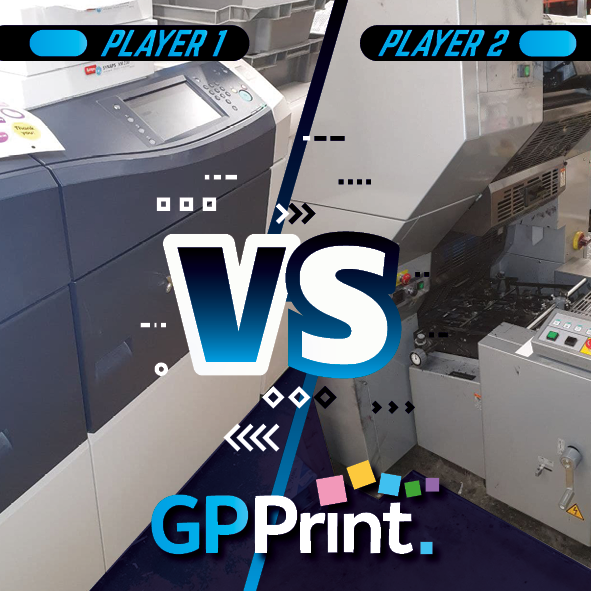

Lithographic Print Versus Digital Print

Mon 14th February 2022

Litho Vs Digital

We are always asked what the differences between the two processes are. The easiest answer is cost. There is a setup involved in operating a lithographic press, for us this is to create plates for the press. Plates are what are used to take the ink from the rollers and make an impression onto a blanket typically made of rubber to transfer that image onto paper (kind of like how a stamp works) these plates will cost more than a certain number of clicks on the digital press. Clicks are what are generally referred to as a counter of sheets through the press. Once the Litho (shorter term for lithographic) press has been set up the cost per sheet is far less than the click rate of a digital press but it takes a number of these before the two cross paths, usually about 1000 sheets.

The second difference is the quality of print, although digital has come a long way from the early days and in most cases today people cannot tell the difference between the two it is still not without its quirks. Digital prints tend to struggle with gradients and some tones.

The other difference is that the toner which is the ink that the digital press uses will sit on top of the paper so it doesn’t matter what type of paper you use it will always appear with an element of sheen. Unlike litho which will soak into the paper if able, papers such as coated stocks will also sit on top of the paper and take a little while to dry whereas digital dries instantly. Uncoated stocks on litho will allow the inks to soak into the paper giving a flatter print. This is a trend that is currently quite fashionable as it can look very earthy and natural.

The last thing is that due to the process of running digital there is a high temperature applied to the paper in order to harden the toner powder on the sheet. Due to this it can often make the paper brittle when folded without scoring firstly. Scoring is when the card has a crease line made into it, often using a matrix of a male and female tool applied to the card at pressure to enable it to be easily folded by hand or machine thereafter without cracking the print or surface of the card. This is mostly effective on card rather than paper as it does not leave as much of a defined indentation in paper as it does in card. Also the heat applied to the paper can draw out the moisture from the substrate causing it to be a little weaker than before, or causes shrinkage albeit very little across the overall sheet. This weakness can make single side laminated paper become curlier than usual as it isn't able to withstand the resistance. Lamination is a skin of plastic usually with either matt or gloss finish.

One major difference is when being overprinted such as a letterhead, if we print with a digital print and you overprint using a laser the ink may pick off due to the fuser temperature. We recommend Litho for use with a laser printer or try to see if ok before ordering lots. Alternatively if using an inkjet to overprint it really doesn't matter.

As previously suggested digital has very little effect on the majority of prints and is widely used as most effective for small to medium sized runs or of prints that change per print such as variable data prints. We use ours for lots of orders of stickers, packaging, books and short run leaflets.

Best Wishes,Peter Martyr

GP Print LTD.